Smooth running of vehicles and machinery is paramount in today’s automotive industry. Downtime, unexpected breakdowns, and maintenance-related problems may have a huge impact on the production lines by delaying deliveries and causing expensive repairs. That is where predictive maintenance comes in, with technological backing from Dynamics 365 and the Internet of Things. Let’s dive into how these technologies help solve some common challenges in the automotive industry and lead to more efficient operations.

The Problem with Traditional Maintenance

The current pace of the automotive industry is fast, and the adoption rate for innovative maintenance methods is not very high. Companies normally follow either the reactive maintenance route by repairing machines after they have broken down or preventive maintenance, where regular servicing is scheduled based on time and unrelated to actual need. Both approaches have drawbacks.

This leads to unscheduled downtime with machines only being fixed after they break, which can stall production, miss deadlines, and cost a huge amount of money. On the other end, performing maintenance too frequently without actual wear and tear as a trigger could be inefficient and very expensive. Moreover, it is usually performed by replacing parts that might have a lot of life left in them. Neither approach provides the ideal balance.

What the Automotive Industry Needs

The smarter the maintenance management in the automotive industry, the better the competitive advantage. Problems should be predicted way before they even happen, minimising unplanned downtime, increasing the longevity of the machine, and reducing the maintenance cost. This is where predictive maintenance powered by Dynamics 365 and IoT comes in.

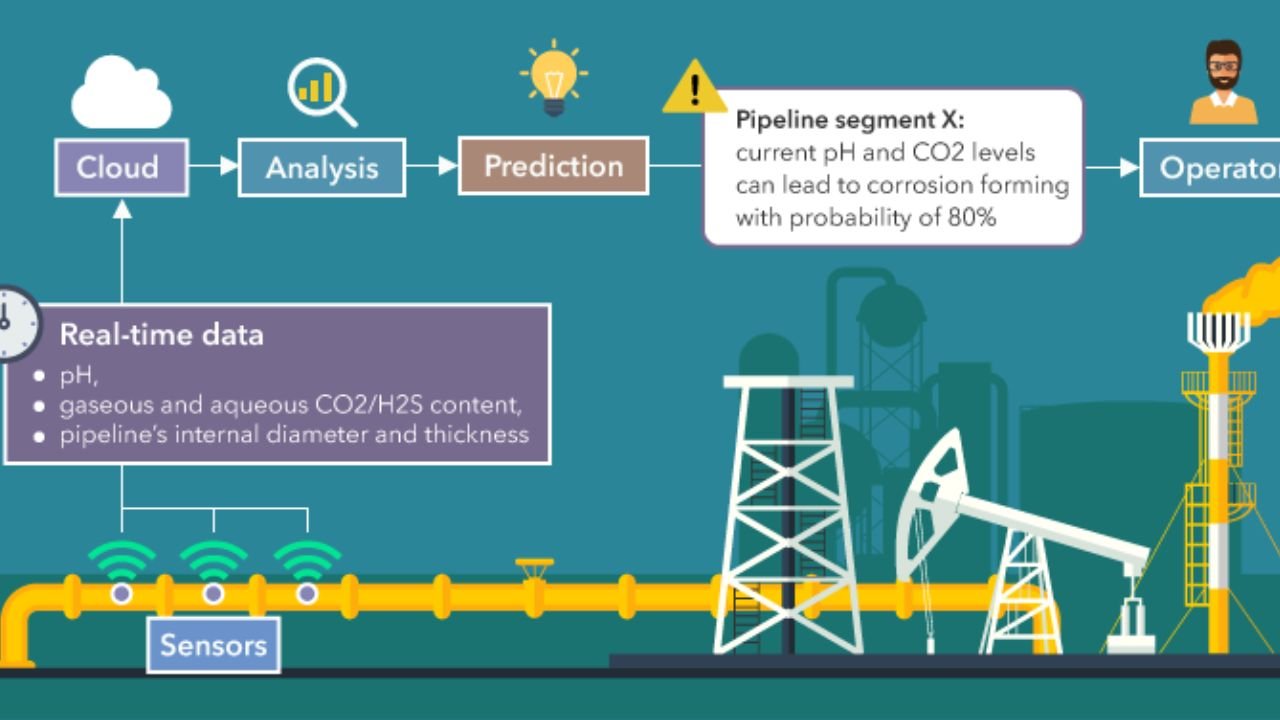

Well, predictive maintenance is pathbreaking in the sense that it makes use of real-time data from the IoT sensors attached to each vehicle or any kind of machinery. These sensors would keep tracing every condition of critical parts like engines, gears, or electricals. These are fitted with the ability to receive data on temperature, vibrations, pressure, and similar parameters. That information is then processed, analysed—key examples are done using Dynamics 365—and a probable time for part failure can be predicted based on condition instead of a fixed time interval.

The Role of Dynamics 365 and IoT in the Solution

By integrating IoT technology with Dynamics 365, the automotive industry will be very proactive in maintenance. This will involve real-time monitoring and analysis to identify problems before they mature into serious issues. Dynamics 365 implementation facilitates the setup of a predictive maintenance seamless system by binding IoT data to maintenance scheduling, inventory management, and overall production workflows.

IoT sensors collect this information and transmit it to the cloud. Dynamics 365, at this point, processes this information to give insights into the possible failures and alert the maintenance teams to act in time. This system eliminates guesswork and ensures repairs or part replacements happen at the exact time needed—neither too early nor too late.

One of the most practical features that Dynamics 365 services deliver is consolidating data across departments. This would mean that the maintenance teams are able to gain real-time access to information on the conditions of equipment so that data-driven decisions can be taken. At the same time, it is integrated with other business functions, such as procurement, ensuring that spare parts are available when they are needed, and production doesn’t come to a standstill because one element isn’t available.

Reaping the Benefits

There are several benefits of implementing predictive maintenance in the automotive industry. First, predictive maintenance dramatically reduces unplanned downtime. In case of uninterrupted monitoring of machines, the potential issues get noticed at a very early stage itself, and the maintenance teams can intervene long before breakdowns occur. This means continuous production lines and cars delivered on time.

Another major advantage involves cost savings. Since maintenance is done only when needed, a company is saved from unnecessary service and repairs. Parts are replaced according to their actual condition, meaning businesses will no longer spend money for replacing components that are still in good condition. All these translate to a lot of savings overtime.

Predictive maintenance also ensures asset longevity. Servicing machines and other vehicles when needed helps them last longer, thus maximising the overall lifespan of the equipment, reducing the need for wisely costly investments into new machinery.

Finally, predictive maintenance with Dynamics 365 improves general productivity. Businesses can maintain a continuous flow of operations without experiencing unwanted downtime by streamlining repairs and replacing parts whenever necessary. Because of Dynamics 365 services, maintenance teams are better placed to make effective decisions, hence improving operational efficiency at all operation levels.

Conclusion

The integration of the Internet of Things with Dynamics 365 is changing the face of predictive maintenance in the automotive industry. It solves some of the critical pain points by tackling unplanned downtime and less efficient maintenance scheduling, instituting in their places data-driven and more productive cost-reducing processes. Companies can now be able to predict and prevent problems by monitoring vehicle and machine health in real time. The combination of IoT and Dynamics 365 will help auto industry companies power their operations to be world class and sustain their competitive edge.

It’s the modern way of maintenance; it doesn’t tend to be a trend but a must for any business looking to optimise workflow, reduce costs, and deliver consistent results. Dynamics 365 implementation in predictive maintenance is hence a step toward a much more reliable and efficient future in the automotive industry.