Introduction

The advancement of precision metal-casting as well as plastic-injection-molding methods meant a total revolution in terms of industrial manufacturing of custom parts in bulk. The accuracy and repeatability of these processes are indeed very high and this makes them lifeline of contemporary production in the world.

What is the casting of metal?

Metal casting is referred to as the process in which molten metal is poured in a designed pattern in such a way that it attains the same shape after cooling and solidifying. A^d as the formal definition of metal manufacturing, but another definition is producing the high-precision metal parts and products in the very harsh environment on the steady large scale.

Metals widely used in casting

- Aluminum

- Steel

- Iron

- Brass

- Zinc Alloys

Varieties of types of metal casting processes

Depending on the design, the application, and on the material to be used in the part, different casting techniques are put into use.

We also have a variety of casting methods which range between prototype work and high volume casting in order to address your particular requirements.

- Sand Casting

Only good when large castings with simpler geometrical properties is involved and production volume is low.

- Investment Casting

Great on precision parts of complex configurations and delicate detail.

- Gravity Casting

The optimality of this processing procedure is well applied in thick walled or very durable yet reliable parts.

What is injection molding with plastics?

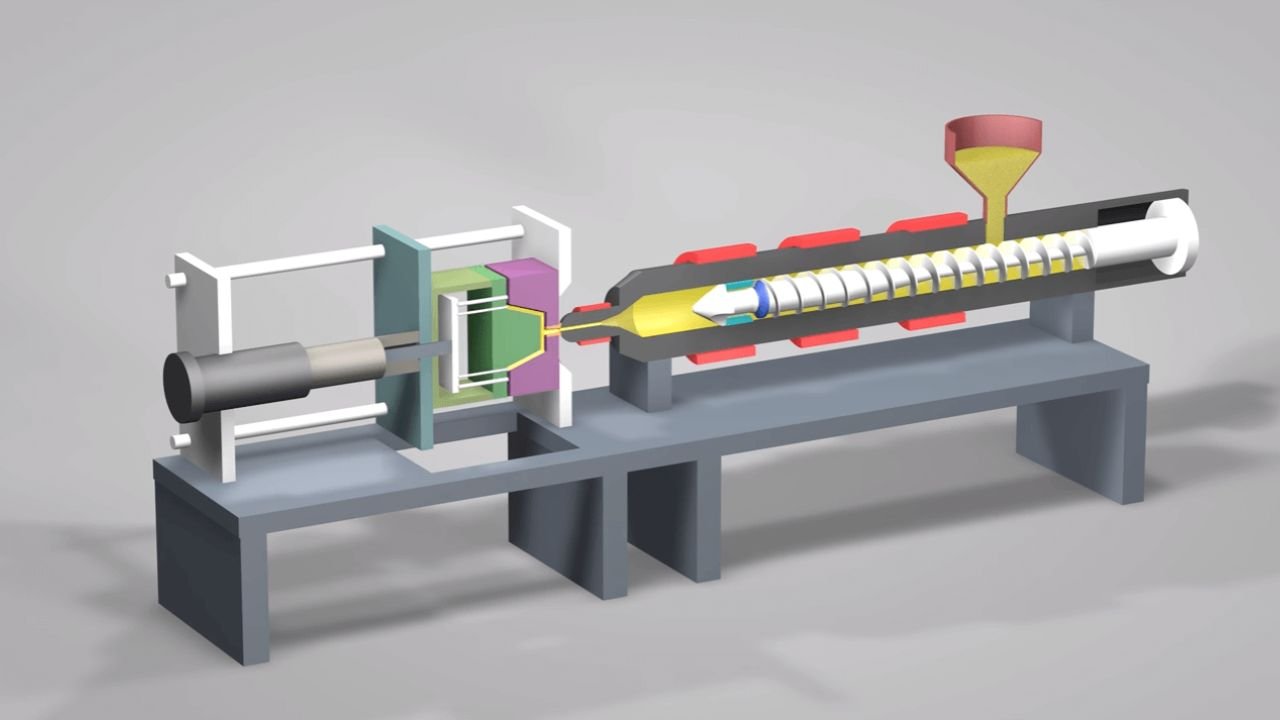

What comes as a surprise to many people is the fact that injection of a molten piece of plastic using a mold tool internally leads to the formation of a part in a given shape as the material flows and attains its solid state through the mold tool.

Plastic injection molding solutions are one of the best ways used by different companies to generate the cheapest plastic parts with high levels of production consistency and with minimal product wastes.

Materials Used in Designs and Constructions Commonly

- ABS

- Polypropylene (PP)

- Polycarbonate (PC)

- Nylon

- POM (Delrin)

Benefits of precision manufacturing solutions

All the advantages that occur as the result of metal casting and the plastic injection molding are exclusive, because of which the various demands under which the broad range of product needs can be met can be achieved.

Due to the following advantages, the global industries ensure that these processes act as one of the dependable methods:

- Cost-Efficiency

Cost effective in mass manufacture

Reduces wastes and material consumption

- Design Flexibility

The approach is effective in handling highly complex components.

With this, manufacturers are able to incorporate threads besides undercuts and logos in their designs.

- Power & Stamina

The level of strength of parts cast metals achieves unprecedented developed strength.

There is a plastic material in various parts that has chemical resistance and it is lightened in weight to improve performance.

General industries served by us

The products offered by the company include globally client base manufacturing solutions to various markets, specifically the automobile markets, as well as, the sub-sectors that include aerospace and medical sectors. The accuracy with which our group carries out precision engineering ensures that every piece renders its performance and safety and durability expectations.

Our casting and molding services benefits the products of the electronic consumer products to heavy industrial equipment applications and many other industries not found in western countries. We are a company that offers fast and precise solutions using trustworthy global services.

What Makes Us the Best Company to Contract with on a Global Manufacturing Service?

The choice of a proper partner to carry out metal casting in conjunction with injection molding processes defines the quality of produced goods as well as the success of the business itself.

Our company works with clients in an entirety of the manufacturing process which includes design and tooling processes to distribution and quality control services to any part of the globe.

Why Shall one work with us?

We have a team of specialists that comes along with technical capacity and engineering and production expertise that dates to whole decades.

We have state-of-the-art CNC machines along with casting machines and molding electronic presses in our site.

High Quality Control ISO certified operations and 100 percent inspection standards

Responsive Support: High-level client managers and clear communication

Conclusion

The global manufacturing plant relies on accuracy casting in metal along with plastic injection techniques to realize the output of efficiency and scaling manufacture. Our individualized service packages give you precise solutions to your performance needs, delivery and cost specifications and the three goals are satisfied.

Be part of the partnership in providing reliable global solutions that combine superior ideas and high performance criteria to realize success in every component of our products.

FAQs:

- What are the products of the precision metal casting procedure?

Strong and inaccurate metal parts delivered industrially to the manufacture of automobiles, aerospace and heavy machines.

- Plastic injection materials?

Typical plastics (ABS, nylon, polycarbonate, and polypropylene) can make good candidates of products that are very strong and lightweight.

- Does the two methods take very complex looking shapes?

Absolutely. Both are highly suitable to very fine detailed, finely finished components.

- Can these services help in large scale production?

Absolutely! The services are large-volume items in regards to manufacture, consistency, and turnaround.

- Are you international?

Absolutely! Our global end-to-end shipping services are done to ensure that your parts reach their destinations safely.